This article mainly introduces the application and advantages of magnetic polishing machines in the polishing process of thermostatic valve cores, and discusses the role of magnetic polishing technology in improving the surface finish of thermostatic valve cores, reducing production costs, and improving production efficiency. It provides an efficient and environmentally friendly polishing solution for my country's thermostatic valve core manufacturing industry.

1. Introduction

With the rapid development of my country's manufacturing industry, thermostatic valve cores have been widely used in aerospace, automobiles, home appliances and other fields. As a key component for controlling fluid temperature, the thermostatic valve core has increasingly higher quality requirements such as surface finish and dimensional accuracy. Traditional polishing methods can no longer meet the needs of modern manufacturing. Therefore, it is imperative to seek an efficient and environmentally friendly polishing technology. As a new type of polishing equipment, magnetic polishing machines are gradually emerging in the field of thermostatic valve core polishing.

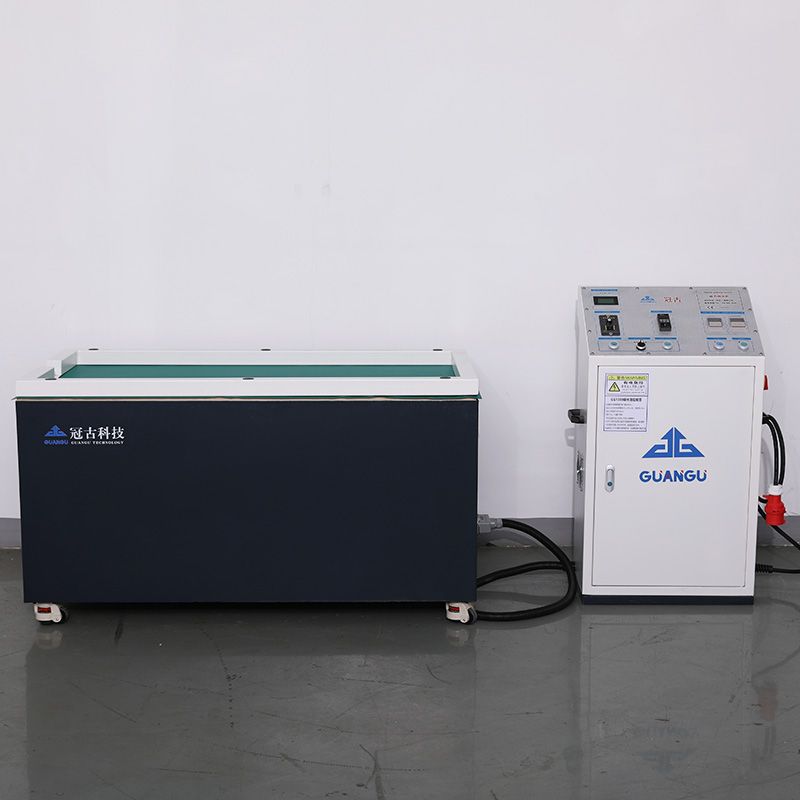

2. Working principle of magnetic polishing machine

Magnetic polishing machines use the movement of magnetic abrasive media in a magnetic field to polish workpieces. Its working principle is as follows: put the workpiece into the polishing machine, add magnetic grinding media and polishing liquid, and generate a magnetic field after power is turned on, so that the magnetic grinding media is close to the surface of the workpiece. Under the action of the magnetic field force, the grinding medium rubs the workpiece at high speed, thereby achieving a polishing effect.

3. Application of magnetic polishing machine in thermostatic valve core polishing

High polishing efficiency: The magnetic polishing machine uses magnetic grinding media, which has a fast polishing speed and high efficiency. Compared with traditional polishing methods, magnetic polishing machines can greatly shorten the production cycle and increase production capacity.

Good polishing quality: During the polishing process of the magnetic polishing machine, the grinding media exerts uniform pressure on the surface of the workpiece, which can effectively remove burrs, oxide scales and other defects on the surface of the workpiece, and improve the surface finish of the thermostatic valve core.

Strong adaptability: The magnetic polishing machine is suitable for polishing thermostatic valve cores of various shapes and sizes, and has good versatility.

Environmental protection and energy saving: The magnetic polishing machine uses water-based polishing liquid, which is pollution-free, and the energy consumption is low during the operation of the equipment, which is in line with the concept of green manufacturing.

4. Advantages of magnetic polishing machine

Save labor costs: The magnetic polishing machine has a high degree of automation and is easy to operate, which reduces the requirements for manual operation skills and saves labor costs.

Reduce the consumption of grinding materials: The magnetic polishing machine uses magnetic grinding media, which has a low wear rate and a long service life, reducing the consumption of grinding materials.

Improve production safety: The magnetic polishing machine polishes in a closed environment, reducing the risk of workers being exposed to harmful substances and improving production safety.

Easy to realize production line automation: The magnetic polishing machine occupies a small area and is easy to integrate with other equipment to realize production line automation.

5. Conclusion

The application of magnetic polishing machine in the field of thermostatic valve core polishing provides an efficient and environmentally friendly polishing solution for my country's manufacturing industry. With the continuous advancement of technology, magnetic polishing machines will play their advantages in more fields and contribute to the development of my country's manufacturing industry.